Employees who perform maintenance or service on equipment and machinery are exposed to the potential for injuries from unexpected release of stored energy in the equipment, energization, or startup of the equipment or machinery. While servicing and maintenance are being completed, the Lockout/Tagout (LOTO) standard requires the implementation of procedures and practices to shut down machinery, isolate it from its energy source, and prevent the release of potentially hazardous energy. To help you with this, we have summarized lock out / tag out procedures for North Jersey facility managers.

Employees who perform maintenance or service on equipment and machinery are exposed to the potential for injuries from unexpected release of stored energy in the equipment, energization, or startup of the equipment or machinery. While servicing and maintenance are being completed, the Lockout/Tagout (LOTO) standard requires the implementation of procedures and practices to shut down machinery, isolate it from its energy source, and prevent the release of potentially hazardous energy. To help you with this, we have summarized lock out / tag out procedures for North Jersey facility managers.

Scope and Application of LOTO

The lock out / tag out standard applies to general industry workers performing maintenance and servicing on equipment and machines and who are exposed to their unexpected startup, release of hazardous energy, or energization. This includes any source of energy, including chemical, mechanical, thermal, pneumatic, and hydraulic.

If your employees maintain, inspect, set up, construct, service, modify, adjust, or install equipment or machines, including the cleaning, unjamming, and lubrication of equipment, where hazardous energy could be released, then this standard applies to them.

Energy Control Programs

One of the core components of an energy control program is procedures that document and detail the information that an authorized employee must know to accomplish LOTO, such as the authorization rules, scope, techniques to be used, and purpose for the control of hazardous energy. Plus, there need to be periodic inspections to make sure that the requirements and the procedures of the standard are being followed.

Employers are able to develop their own programs. However, these employers are expected to create procedures and programs as well as inspections and training that meet the specific requirements of their equipment and machines along with their workplace. They must also meet the requirements of the LOTO standard.

Requirements for Energy Control Procedures

Energy control procedures must include at a minimum:

Energy control procedures must include at a minimum:

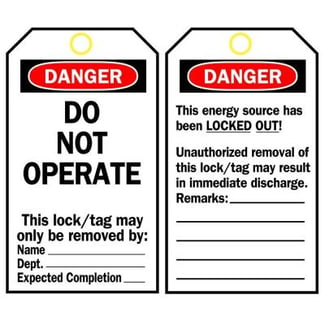

- Specific procedural steps for the removal, transfer, and placement of tag out devices or lock out devices as well as a description of who has responsibility for them.

- A statement of the intended use of the procedure.

- Requirements for testing a piece of equipment or machine to determine the effectiveness of energy control measures, such as tag out devices and lock out devices.

- Specific procedural steps for blocking, shutting down, securing, and isolating equipment or machines to control hazardous energy.

Employees affected by the standard must be trained so that they can understand the function and purpose of the energy control procedures and so they can acquire the skills and knowledge needed for the safe usage, removal, and application of energy controls. The training comes in three levels from most intensive to lease: authorized employees, affected employees, and other employees, who may be in an area where energy control procedures may be utilized.

This is just the tip of the iceberg when it comes to OSHA LOTO guidelines for North Jersey. For a more in-depth examination, visit the OSHA website. For information on lock out / tag out signs for your facility, contact The Sign Center today for a free consultation and quote.